Product news, Ramén Valves, 05 October

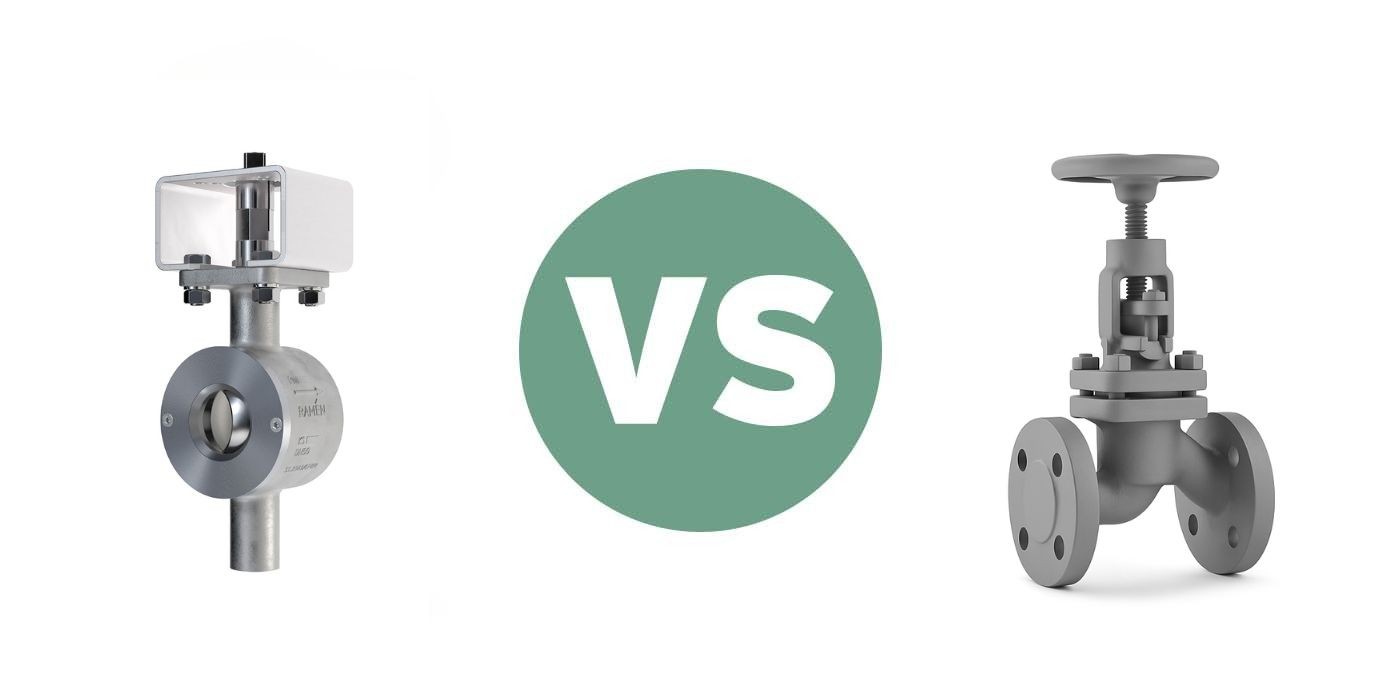

Technical comparison Ball Sector valves vs. Globe valves

Both globe valves and ball sector valves can be used as control valves but have somewhat different advantages and features. In this post we will give you 8 reasons to why a Ramén Ball Sector Valve might be superior to a globe valve in you flow control application.

Superior geometry and valve characteristic

A Ramén Ball Sector valve provides an equal percentage characteristic in a geometry of two circular openings forming an elliptic to circular primary control orifice. Insensitive to particles and other impurities that cause wear and tear, malfunction and insufficient control performance.

Improved capacity and wider rangeability:

The Ramén Ball Sector valve gives a considerable higher Cvs/Kvs value for same size, meanwhile offering an extended control range. This makes the ball sector an excellent solution, especially in higher flow capacities with higher turn-down ratio (Max.flow/Min.flow) in the process.

Low pressure drop

The pressure drop in a Ball Sector Control valve is much lower than any globe valve designs. This is requested in many applications which minimal pressure drop during flow control is required (e.g. fuel supply in burner and furnace system). The Ramén Ball Sector valve in fully open position has negligible pressure drop (i.e. low resistance coefficient or K-value).

Self-draining design

The Ramén Ball Sector valve has no hidden cavities where particles and other impurities might create wear and tear, or thermal expansion damages.

Shut-off tightness

Globe valves are not typically used for applications where a tight shut-off is required although they could be used in combination with a simple on/off ball, butterfly, or plug valve, or any other type of shutoff valve. This option would of course add to the total cost and space requirements. While the Ball Sector valve could give tight shut-off as normal ball valves in both flow direction.

Quarter turn actuation and low torque operation

This makes Ramén Ball Sector Valve more reliable, robust and standardized solution compared to linear actuation in globe valves. Typically Globe valves have high pressure drops, since the pressure exerted is transferred to the valve stem. They also require greater force or a larger actuator to seat the valve. However, Ramén Ball Sector valves operate with low required torque which lower the need for use of bigger actuators saving cost and space in many applications.

Compact design

The compact wafer design with a quarter turn actuator create a simpler installation and easier maintenance for end users. The compact design, together with higher capacity, compared to globe valve, makes the Ball Sector valve a light solution, lowering heavy loads in piping installation.

Overall lower Life Cycle Cost (LCC)

Considering the low maintenance requirements, a significant resistance against wear and tear and the compact design with a higher capacity the Ramén Ball Sector Valve is an excellent cost conscious purchase for end users compared to globe valve designs in many control applications.

Are you interested in getting more information about Ramén Ball Sector valves or learn more about control valve sizing in general?

Language

Language Swedish

Swedish English

English