Ramén Valves, Uncategorized, 16 April

The differences between Ball Sector valves and Segmented ball valves

It is a common misconception that the Ramén Ball Sector valve and segmented ball valves are the exact same or at least very similar types of control valves. In reality they have different features and fulfills different needs. In this technical comparison you will find out about some of the differences between a sector and a segment.

Geometry plays an important part

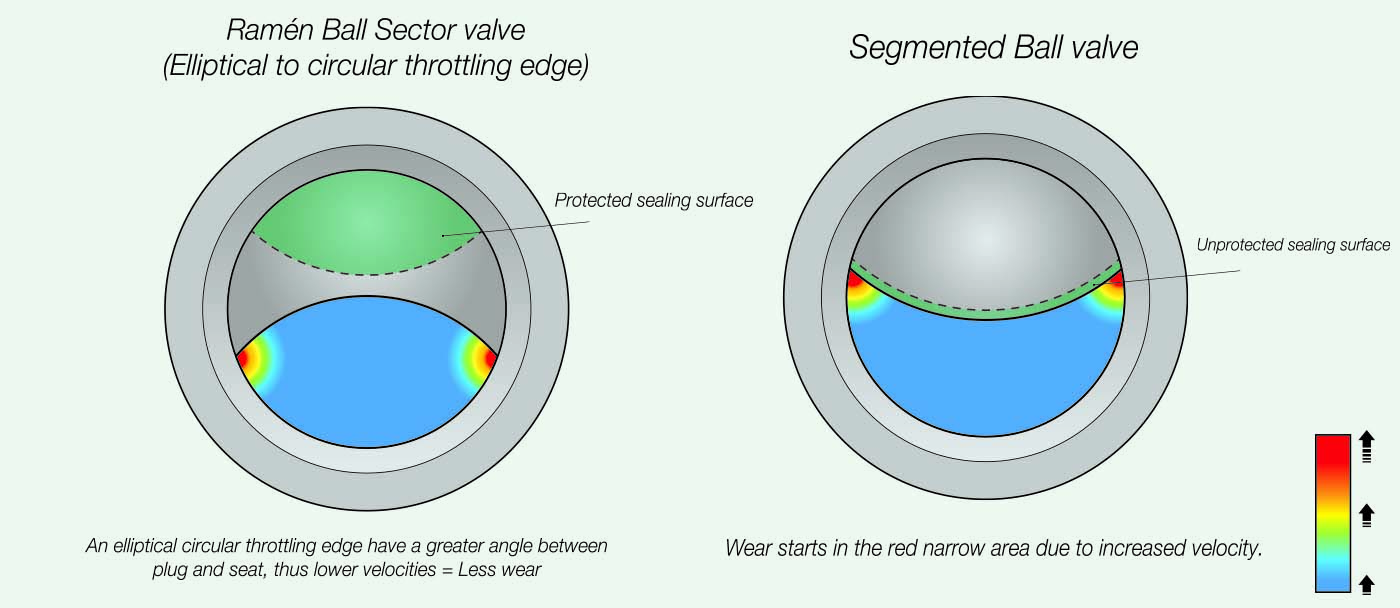

The Ramén Ball Sector valve have two circular openings where one is static (the seat) and the other one is dynamic (the ball). When these to openings intersect and move apart horizontally, they create and elliptical geometry that is very beneficial. It is beneficial because it protects the critical surfaces from high velocity and thereby wear and tear.

Then we have the Segment ball valve design that have one static circular opening with a circular body, forming a moon crescent geometry when moving apart horizontally. This geometry gives v-shaped corners where velocity inevitably increases. The high velocity cause wear and tear which shorten the service life of the valve.

In addition, because of the specific design of the Ramén Ball Sector Valve, the seat sealing surface (in green in the picture below) is always protected from abrasion, while it is directly exposed in Segmented ball valves. The Ramén Ball Sector valve seat is fully protected by the ball sector in the open position and fully supported from 0° to 90°, whereas in segmented ball valves the seat is fully exposed to media and there is no segment support in the open position. This offers an increased wear-and-tear resistance for abrasive media and a secured tight shut-off with any media.

Equal vs. linear percentage characteristics

The Ball Sector valve has an equal percentage characteristic with a range up to 300:1, while the segmented ball valve usually has a linear percentage characteristic. The advantage with an equal percentage valve is that it can manage any process independent of the deltaP.

Bi-directional design

Ramén Ball Sector Valves have a bi-directional design whereas segmented ball valves have usually one flow direction as standard. This means that the Ramén Ball Sector Valve can be installed in both direction without any impact on the controllability or tightness of the valve. In fact, it is more appropriate to mount the valve body in the opposite direction when controlling abrasive media. With the throttling orifice placed on the outlet side of the valve, velocity and thereby abrasion in the valve body is avoided.

Language

Language Swedish

Swedish English

English