Ramén Valves, 05 May

Ball Sector valve seat materials – What’s the difference?

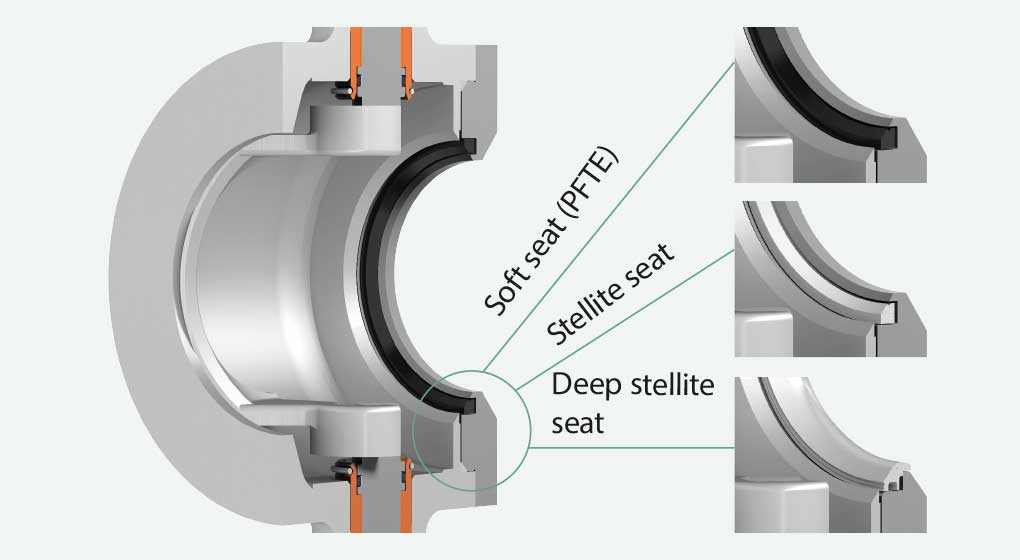

The Ramén Ball Sector valve is offered in a variety of configurations. They may look the same on the outside, but there is a significant difference between the models and it is all in the seat and ball sector material. In this post you will get a brief explanation of what the differences are between KS-1, 1A, 1B 1C and 1E.

KS-1 (Soft seat PTFE)

Ball sector control valve KS in execution 1 with stainless steel body and ball sector and carbon/graphite PTFE seat. Natural choice for clean and non-abrasive liquid or gas at moderate pressures, pressure drops and temperatures.

KS-1A (Soft seat PTFE)

KS in material execution 1A with hard chrome-coated ball sector, and soft PTFE seat ensures class VI shut-off. Excellent choice for wastewater, fibre suspensions and some abrasive media.

KS-1B (Stellite seat)

KS in material execution 1B, a Stellite metal seated valve with hard chrome-coated ball sector ensuring class IV compliance in shut-off services. Suitable for many abrasive fluids containing hard particles at elevated velocities and temperatures.

KS-1C (Stellite seat)

KS in material execution 1C, metal seated with hard chrome-coated ball sector and seat holding ring with increased protection against abrasion ensuring extended service life for throttling high-velocity process fluids.

KS-1E (Deep stellite seat)

KS in material execution 1E, with deep Stellite metal seat offering long service life for any applications with highly abrasive media containing hard particles within the pulp & paper industries, mining, wastewater in steel mills, sewage plants and many others.

Language

Language Swedish

Swedish English

English