Optimal pressure control with pressure regulators

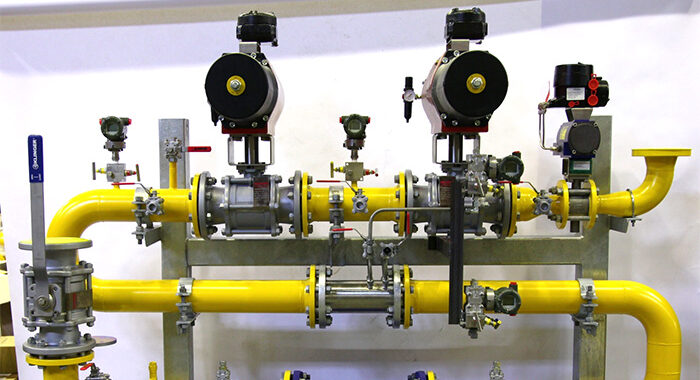

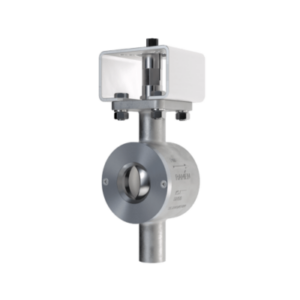

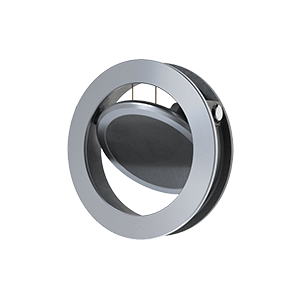

Pressure control is crucial for the safe and efficient operation of gas systems. Two key components in maintaining optimal pressure levels are Pressure Reducing Regulators and Back Pressure Regulators. Ramén Valves offers a wide range of regulators from Cashco, known for having some of the most versatile regulators on the market. In this article, we will explore the different types of regulators and their specific functions.

Language

Language Swedish

Swedish English

English