From water to energy – Valve solutions for electrolyzers

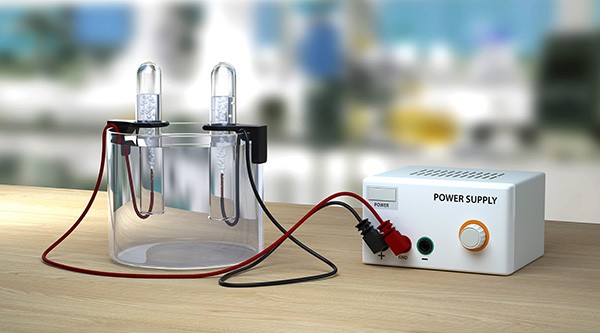

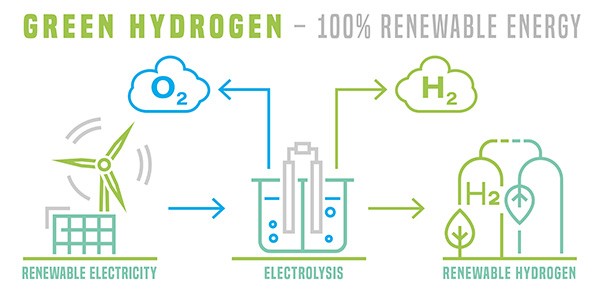

Electrolysis is one of the most widely used methods for producing hydrogen. Though there are several approaches, the basic principle is always the same. Water is split into hydrogen and oxygen with the aid of electricity. Electrolysis for hydrogen production is considered a sustainable method because it can utilize electricity from renewable sources such as solar or wind power, resulting in the generation of "green" or renewable hydrogen. This hydrogen can then be used as a clean energy carrier in fuel cells, transportation, industrial processes, and other applications without producing greenhouse gas emissions.

Ramén Valves offer valves suitable for every size of electrolyzer. Our valves from HEROSE deliver superior performance in both low-pressure and high-temperature environments. With our in-stock availability and competitive pricing, we deliver solutions that match your needs, whenever you need them.

Valves for all electrolysis technologies

Four distinct technologies are recognized in electrolysis:

- Alkaline Electrolysis (AEL)

- Proton Exchange Membrane Electrolysis (PEM)

- Anion Exchange Membrane Electrolysis (AEM)

- High Temperature Electrolysis (SOEC)

Our valves protect your system no matter what technology you use.

Key challenges with electrolysis

Although the use of fossil-free electricity in the electrolysis process for hydrogen production has significant climate-friendly benefits, the efficiency is relatively low and leads to an energy loss of around 20-30%. Progress is being made in research and development to improve efficiency, but challenges such as reducing the cost of the technology and infrastructure and ensuring a stable and sustainable supply of renewable energy to power the electrolysis remain.

The difference between the different electrolysis technologies

Alkaline Electrolysis (AEL)

In AEL, an alkaline electrolyte, typically a solution of potassium hydroxide (KOH) or sodium hydroxide (NaOH), is used. This method is the oldest and most established for hydrogen production and is often used in large-scale industrial applications.

Advantages: low cost and proven technology

Drawbacks: the need for purified water and sensitivity to impurities

Proton Exchange Membrane Electrolysis (PEM):

PEM electrolysis utilizes a solid polymer membrane to separate the anode and cathode.

Advantages: High efficiency and rapid response time

Drawbacks: Higher costs and increased sensitivity to operating conditions

Anion Exchange Membrane Electrolysis (AEM):

Similar to PEM electrolysis, AEM electrolysis uses an anion-conducting membrane instead of a cation-conducting membrane.

Advantages: Cheaper catalysts and less sensitive to impurities

Drawbacks: The need to handle hydroxide ions and membrane stability over time.

High-Temperature Electrolysis (HTEL):

HTEL utilizes high temperatures, typically above 700°C, to drive electrolysis. This enables the use of solid electrolyte cells, typically made of ceramic materials, that can operate without using liquid water.

Advantages: highly efficient and can take advantage of heat from other processes

Drawbacks: requires advanced materials and management of high temperatures

Recommended valves for electrolysis

Below you will find a selection of valves from HEROSE that we at Ramén Valves recommend for electrolyser.

Explore our range of valves through our product platform by clicking on the links below. In the product platform you will find detailed pricing and delivery information. If you need help selecting the appropriate valve for your process, feel free to contact our technical specialists via our live chat for immediate assistance.

HEROSE safety valve model 06383. Protects electrolysis systems up to 100 MW from overpressure.

HEROSE globe valve FullX 11C01. Eliminate leaks and heat loss in hydrogen applications with HEROSE FullX.

HEROSE globe valve 01741. Globe valve in stainless steel, approved for air vapours, gases and cryogenic liquefied gases such as H2.

Contact us

Language

Language Swedish

Swedish English

English