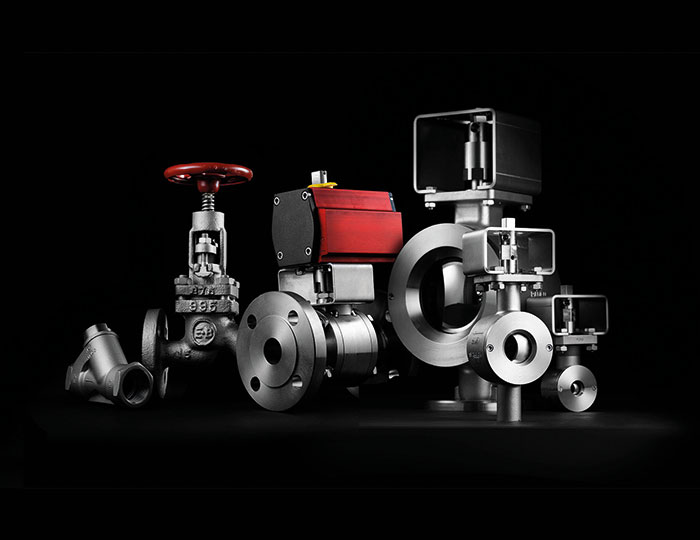

High-alloy valves built for the harshest conditions

We engineer and manufacture high-alloy valves to meet exact end-user specifications, using exotic and nickel-based alloys such as 254 SMO, Duplex, 904L, Monel and more. Installing a high-alloy valve provides a reliable solution to challenges such as oxidation, corrosion, extreme temperatures, and high pressure in harsh operating environments.

Key benefits of high-alloy valves

Corrosion resistance

Suitable for marine, offshore, and chemical applications.

High strength in extreme temperatures

Performance from cryogenic to very high temperatures.

Long service life

Reduced maintenance and downtime.

Custom engineering

Tailored designs for unique operating conditions.

Our selection of high alloy and titanium materials

- 316 (EN 1.4436)

- 316L (EN 1.4435)

- 904L (EN 1.4539)

- 254 SMO (EN 1.4547)

- Duplex (EN 1.4462)

- Superduplex (EN 1.4410)

- Titanium ASTM grade 2 and grade 5

- Hastelloy C-276

- Alloy 20 ASTM A265

- Inconel

- Monel

Valve types we offer in exotic materials

- Ball valves

- Check valves

- Ball Sector valves

- Butterfly valves

- Gate valves

- Vacuum valves

- Globe valves

Alloy comparison guide

When choosing the right valve material for your process it is important to be aware of its inherent characteristics. Down below you find a comparison between some of the alloys we use to manufacture valves.

316L

- Common standards: EN 1.4404, UNS S31603/S31600)

-

Applications: Food, pulp, marine, and chemical industries.

-

Corrosion Resistance: Basic resistance; prone to pitting/crevice corrosion.

-

Acid Resistance: Handles up to 1.5% HCl at 80°C.

-

Chlorides: Limited to ~1000 ppm at up to 90°C.

-

Strength: Economical choice for less harsh conditions.

904L

- Common standards: EN 1.4539, UNS N08904

-

Applications: Chemical, petrochemical, and seawater use.

-

Corrosion Resistance: Higher than 316L; similar to Duplex 2205.

-

Acid Resistance: Good in dilute sulfuric, phosphoric, and organic acids.

-

Chlorides: Withstands ~10,000 ppm but susceptible to crevice corrosion.

Duplex 2205

- Common standards: EN 1.4462, (UNS S32205/S31803)

-

Applications: Oil & gas, seawater, food, and scrubbing systems.

-

Corrosion Resistance: Intermediate—better than 316L, below 254SMO.

-

Acid Resistance: Effective in up to 2% HCl at 75–80°C.

-

Chlorides: Comparable to 904L; weaker than 254SMO in harsh environments.

Super Duplex

- Common standards: EN 1.4410 (UNS S32750)

-

Applications: Offshore oil & gas, desalination, tanks, exchangers.

-

Corrosion Resistance: Excellent pitting/crevice resistance; top-tier strength.

-

Temperature: Good up to 600–950°C; embrittlement risk at 475°C.

-

Chlorides: Resistant up to 6% FeCl₃; CCT ~80°C, CPT ~50°C.

-

Acids: Effective in sulfuric and hydrochloric with low corrosion rate.

254SMO

- Common standards: EN 1.4547 (UNS S31254)

-

Applications: Marine, chemical, pharma, oil & gas, high temp/cryogenic.

-

Corrosion Resistance: Outstanding—best among listed steels.

-

Acid Resistance: Performs in up to 3% HCl at ~90°C; good in various acids.

-

Chlorides: Resists >10,000 ppm from 20–90°C.

-

Best for: Extreme corrosion and complex geometries

Titanium Grade 2

- Common standards: (TiGr2, UNS R50400)

-

Applications: Desalination, marine, chemical, heat exchangers, 3D printing.

-

Corrosion Resistance: Excellent in seawater, acids, chlorides.

-

Strength: Moderate; better than Grade 1.

-

Temp Resistance: Continuous up to 800°F (426°C), intermittent up to 1000°F (538°C).

Titanium Grade 5

- Common standards: (TiGr5 / 6Al-4V, UNS R56400)

-

Applications: 3D printing, aerospace, marine, chemical, tooling.

-

Corrosion Resistance: Good; lower than Grade 2 in some media.

-

Strength: High strength, heat treatable, ductile.

-

Temp Resistance: Up to 600°F (316°C) in service.

Language

Language Swedish

Swedish English

English