Valves for air separation plants

Cryogenic air separation is nowadays one of the most proven methods for separating air into its components on an industrial scale. New air separation plants are regularly built or existing plants are overhauled, revised or expanded. Valves play a critical role in air separation plants and depending on where in the process the valves are applied they carry different challenges.

Ramén Valves offer valves from HEROSE that cover all the stages in the process, from air compression, cooling and purification, over rectification to final storage and distribution.

10,000 liters of air are flowing through our lungs every day and oxygen is constantly produced for our bodies. What a person can do in a day, can be sucked in by an air separation plant in just 1-2 seconds. Components of air are extracted for industrial purposes on a large scale by air separation plants. Ramén Valves have the valves needed for this process.

Find out more about our products from HEROSE for air separation below.

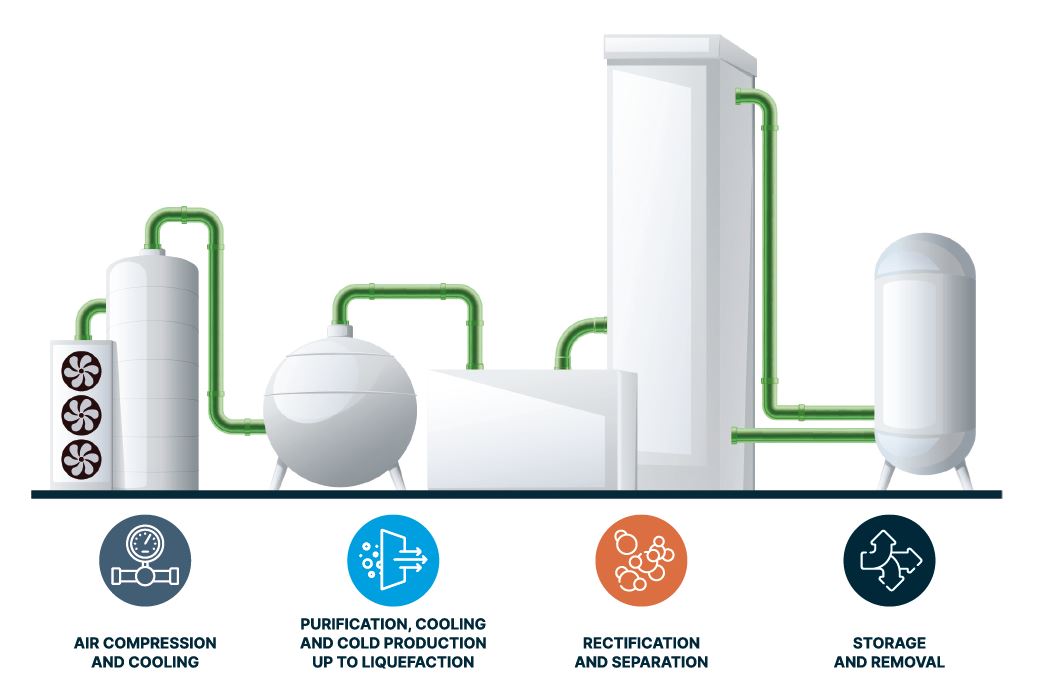

The different stages of an air separation plant

- The ambient air is first drawn in through a filter and compressed.

- The air is then cooled and unwanted impurities such as dust and carbon dioxide are removed in the absorbers.

- Through heat exchange and expansion, the air is further cooled down until it reaches a temperature between -170°C and -193°C.

- The different pressure levels and temperatures make it possible to separate the components of the air according to their state (liquefied or gas) and store them in storage tanks or make them directly available.

Our valve solutions for air separation

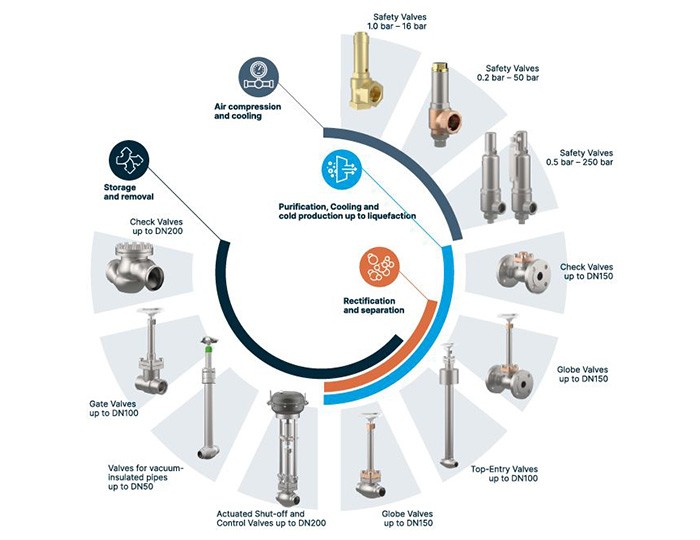

No matter how cold it is – our valves from HEROSE specifically designed for air separation plants feel comfortable to work under extreme conditions. From compression and cooling, over liquefaction and rectification up to storage and extraction you can find HEROSE valves in the different processes of air separation plants:

- Air compression and cooling

- Purification, cooling and cold production up to liquefaction

- Rectification and separation

- Storage and removal

Find out more about the products below or contact us to get more information.

Our valve solutions for air separation

See below the valves we offer from HEROSE for each stage of the air separation process.

Air compression and cooling

Safety valve type 06370

Safety valve type 06420

Cooling and refrigeration up to liquefaction

Globe valves

Rectification and separation

Globe valves

Storage and removal

Globe valves

Gate valves

Contact us

Use the form to contact us.